Lamplbräu Beer

Friday, November 4, 2011 at 9:00

Friday, November 4, 2011 at 9:00 At the end of our tour of the Lamplbräu brewery, Herr Stanglmayr kindly gave us a 6 pack with three of his pils and three of his weißbier to try, and we picked up some helles at the Deutsches Hopfenmuseum.

The helles was quite good. A smooth, classic helles style beer. Easy to drink, but with a good light hoppiness (from Hallertau hops, of course!) and just the right carbonation. When we visited the brewery, he had already sold his last batch of helles (apparently it goes quickly!), but we were able to pick up a six-pack at the Hopfenmuseum.

We'll have to try it up against Tegernseer and some of the better Munich helles, but we think it would stand up quite well in another beer tournament!

The pils was also much to our liking, not surprising for a southern Bavarian pilsner-style beer. It was a more hoppy beer, but not at all bitter. Very enjoyable.

Note the different bottle style - he had had some trouble with the bottles he normally used for pils and ended up having to use a different one. So it may be that this batch will be in a different bottle than ones we would get at another time.

As you can probably tell from the lights, rides, and people passed out on the hill, we tried these at Oktoberfest (as part of our engagement picnic).

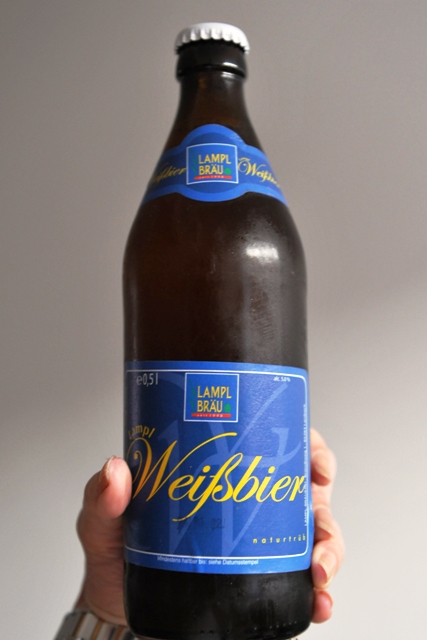

On a later day, we tried the Weißbier.

We are big fans! This is a great weißbier, and one that will please both weißbier lovers and those who find it too sweet. While it does have hints of the weißbier flavors, it is not at all sweet and is very subtle (but complex) in the flavoring. No one aroma or taste overpowers the others - it's quite a nice balance. Also an unfiltered weißbier, and one that is not too fizzy. We'll have to get some more of this!

Frau A ...

Frau A ...  Post a Comment

Post a Comment